If you need products, assembly lines or perhaps the table in the meeting room, to be disinfected, we have a solution. Disinfecting surfaces with UV light is an effective and environmentally friendly way to protect yourself against viruses, bacteria, and fungi that could otherwise be transferred from one device to another or from one human to another.

In 2020, the world got hit by a pandemic and due to population density, pandemics will likely occur more frequently in the future. That is why it is important to be able to take care of your customers, employees and partners. Among other things, this applies to disinfection of surfaces that many people are in contact with.

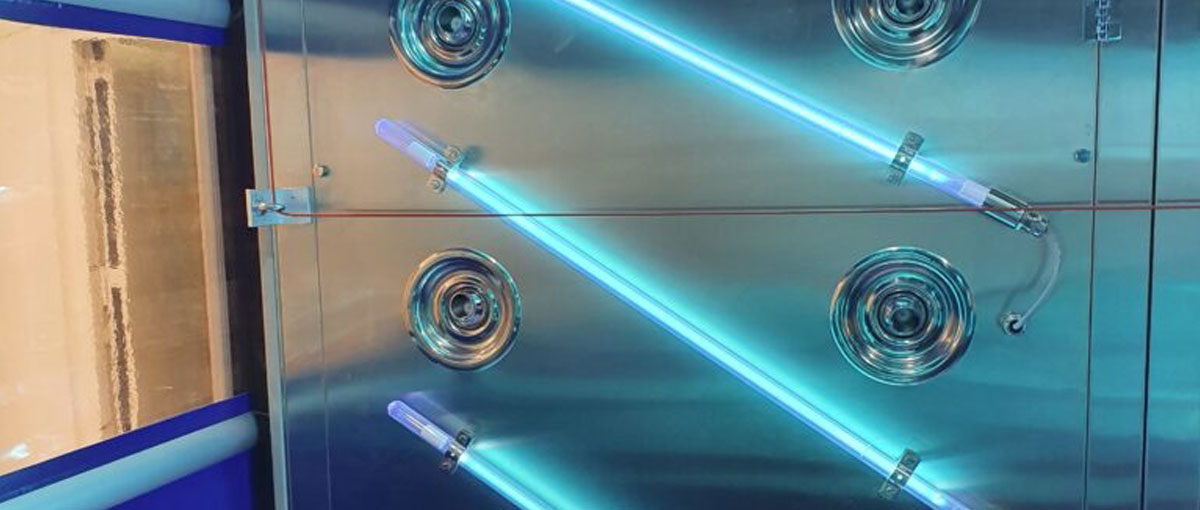

Especially in the pharmaceutical and healthcare industries, it is important to disinfect surfaces. In a laboratory, contamination can be stopped by thorough disinfection, and UV light is an obvious choice here – for example for disinfection of instruments and tools through our CleanBox.

Disinfection on surfaces in:

- Cleanrooms, laboratories

- Offices, meeting rooms, canteens

- Conveyor belts, assembly lines

- Sluices and entrance rooms

- Approved for contact with food

Read more about our products for disinfection of surfaces: