We received a customer case with the following task:

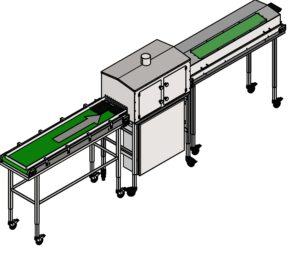

Build a UV-tunnel that fits into the existing production setup. The tunnel must fit in a small space and be moveable for cleaning etc. The tunnel must also be flexible in terms of capacity and height. The tunnel must could be disassembled into 3 parts in 2 minutes.

The UV-tunnel must deliver enough UVC dose to ensure a D99 of the pathogen, which is particularly undesirable here. The surfaces must be disinfected at 360°. The tunnel must be easy to use and have good service access. The belt speed must be 4 meters/minute with the possibility of adjustment. The system in UV-tunnel must be future-proofed, so it can adapt to the changing requirements in the future.

And here it is – created for the customer.

Why is the exit lane covered?

The entire UV-tunnel will be located in an unclean area, but the disinfected items are delivered to the clean room. That’s the reason why the exit belt is closed with a smart acrylic plate at the top. With the acrylic plate it is possible to look in without the UVC light being able to get through.

In fact, the UV-tunnel was lucky enough to be in some video recording, which you can see more about on our website.

Contact us for your new solution here